By Charles Scott Williams of the B-29/B-24 Squadron via CAF On The Fly

For the past two days, I had the pleasure of working on the B-29 Superfortress FIFI. My assigned task was to help install the carburetor on the #1 engine. This massive contraption for the R3350 engine weighs somewhere in the ballpark of 35 pounds and sits atop the aft portion of the engine. Seems like a simple task. Sit this heavyweight carb on it’s designed position and simply install a few washers and bolts to hold it in place. After that simple task, run the aircraft safety wire through all the bolts to prevent them from loosening. Easy Peasy! There are just a few small issues in doing all this; no worries, I’ll list them in the following paragraphs. The engines in the B-29 are located several feet above the floor so you work on the aircraft via ladders and or a B-4 stand. Once within reach of the openings on the engine nacelle, options to access working on the engine include; dangling from the top nacelle opening, stretching across the side nacelle openings, or as demonstrated by my Maintenance Supervisor for the day, Colonel Scott Lewallen, you can squeeze into the nacelle. Ergonomics and Human Factors were words that seemingly, were not in the vocabularies of the engineers that designed WWII aircraft. I’ve said it before, and I will say it again (sans profanity), I wish the engineer who designed the aircraft (insert type) would have to work on said aircraft.

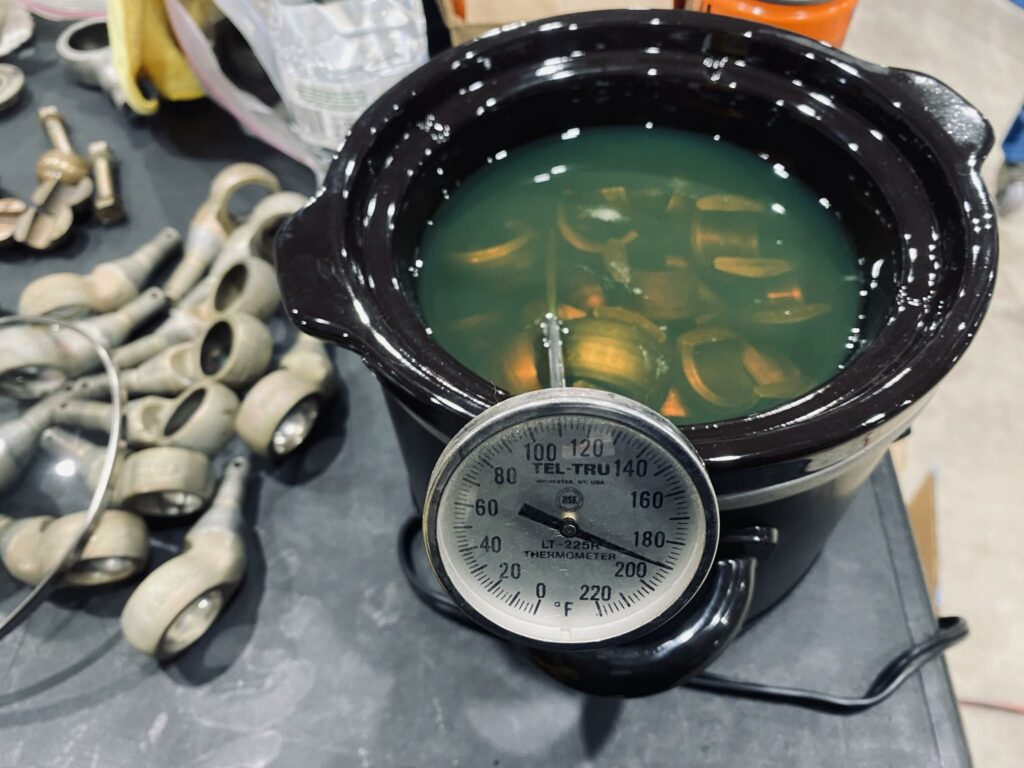

OK, start with sitting the carburetor on its position atop the engine. Don’t forget to install the gasket first! Insert the concave washer correctly on the bolt, then insert the bolt into the attachment hole where it belongs. Here’s where the mental anguish begins. As you reach to insert the bolt, in the back of your mind you’re saying to yourself; “don’t drop the bolt and washer, don’t drop the bolt and washer, please God, don’t let me drop the bolt and washer.” If you do drop ANYTHING whilst working inside the engine nacelle the first thing anyone within earshot hears is a loud profane statement, followed by a clanging sound as the dropped device; bolts, washers, tools, find their way into the dark abyss of tangled hoses, cables, and engine components far below. “Safety first!” says the unit Safety Officer and he/she is correct. You can’t simply abandon a tool or parts that fall into the nacelle and just go buy a new wrench or retrieve a new part. Ya gotta find this stuff and remove it from where it doesn’t belong because it can cause problems in the operation of the aircraft. Cables can get jammed by a wrench, etc. During this assignment, I dropped a screwdriver once, and a wrench once. Both were found with relative ease and the task at hand was carried on.

(adsbygoogle = window.adsbygoogle || []).push({});

Like the movie Highlander where “there can be only one”, in my experience in aircraft maintenance, there is always ONE: ONE problem bolt that won’t work, ONE seemingly impossible task at hand due to the lack of working space. But in fact, with the R3350 carb, there are MANY issues due to the design of this machine that doesn’t account for the need to use a wrench and get a finger and thumb on a bolt to turn it. Day one, I spent hours trying to tighten that last carb bolt that is located in a space beneath the aft portion of the carb. No dice.

After a night of sleep and returning with a rested mind, a surgical clamp, a tool I’ve never used as I attended flight school instead of medical school, saved the day. Turning the bolt to tighten it suddenly started working as I used the surgical clamp to grasp the bolt and get it down to the point of tightening. Amazing how much joy was experienced when a single bolt starts threading its way into the attachment point! Now to tighten. Yoda taught Luke Skywalker how to use the force, and Colonel John Schauer handed me an angled 9/16th wrench. Yoda said to Luke “Feel the force,” said John, “Use this and you can turn the bolt 1/16th of an inch at a time.” Just like Luke using the force to lift that X-Wing fighter out of the swamp on the planet Dagobah (very similar to Houston in humidity), the mighty angled 9/16th wrench tightened the bolt! Using the right tool, imagine that, the task is accomplished.

(adsbygoogle = window.adsbygoogle || []).push({});

Now to the safety wire. Each bolt has holes for threading safety wire, and thus you run this wire through the bolt so that the tension via the wire prevents the bolt from coming loose and turning to the left. Righty tighty, lefty loosey. Again, with the engineer who designed this carb, I wish he was alive to be forced to try running safety wire throughout a series of bolts. If he wasn’t bald-headed, he would be after trying this because he’d pull all his hair out in frustration. And, I would acquire happiness in watching him do this. But, he’s long dead and I have to get the job done. At stage right, enter Colonel Scott Lewallen to save the day by squeezing his entire body into the cramped nacelle and loosening the bolt to a position in which the safety wire could be inserted. Watching Scott loosen the bolt that took me hours to tighten caused mental pain for me having found a moment of Zen after finally getting that darn thing sinched down. Upon retightening, the safety wire was in the correct position and the bolt was tightened with the lightsaber a.k.a. an angled 9/16th wrench!

My work partner for the day was Colonel Ken Pierce, and as Ken had done this before, I learned much from him. Thanks to Colonels Scott Lewallen, John Schauer, and Ken Pierce for all their mentoring in my quest to someday obtain my A&P License. Learning the B-29 inside out will make me a better Flight Engineer, and a couple of seasons down the road, a better Co-Pilot on this wonderful aircraft. My DNA now rides in FIFI as I shed blood helping install the carburetor on the #1 engine. As Yoda would say: “Bragging rights you have, having installed a carburetor on a B-29.”

Check out the CAF AirPower History Tour and see the B-29 live in person! You can find their tour dates here.